CORE CRACKS

Possible Causes

• Blade too hard for the material being cut.

• Excessive cutting pressure, caused by too high infeed results in the blade core bending and flexing. Metal fatigue will eventually cause core to crack.

• Worn shafts, damaged machine bearings, or blade incorrectly mounted.

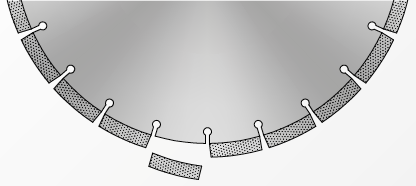

OUT OF ROUND

Possible Causes

• Blade shaft bearing may possibly be worn. Fit new bearing and ensure regular lubrication.

• Blade too hard for the material being cut, this will result in the blade hammering and wearing out of round. Choose a blade with a softer bond system.

• Machine spindle may have groove scored in it as result of previous blade slipping on spindle.

DAMAGED ARBOR HOLE

Possible Causes

• Blade will hammer if it is incorrectly aligned when mounted. Make sure that the blade is mounted on the correct diameter spindle before tightening. Make sure that the pin holes slide over the drive pin.

• The blade will spin or vibrate on the spindle if the flanges are not properly tightened.

• The blade will pound if the saw shaft is badly worn or grooved.

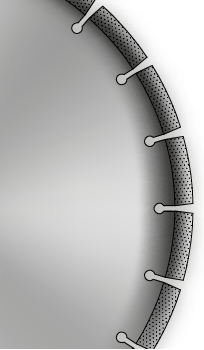

SEGMENT LOSS

Possible Causes

• Blade has twisted or jammed in the cut because the material was not held firmly.

• Machine has been twisted or turned while blade is in the cut.

• Blade core has undercut due to cutting below the asphalt into the sub-base.

• Blade is too hard for the material being cut, resulting in the blade hammering in the cut.

• Blade is deflected in the cut due to the blade flanges being worn or deformed and failing to provide proper support.

• Inadequate water supply.

OVERHEATING

Most common cause of blade failure. Overheating can cause many other problems such as core cracks, loss of tension, and segment loss.Overheating will usually cause black or bluish discoloration on the core.

Possible Causes

• In wet cutting:

Inadequate water supply due to low water pressure, blocked or damaged water tubes or dust suppression systems being inadequate for wet cut blades.

• In dry cutting:

Excessive cutting pressure results in heat build up. Allow blade to do work, with hand held machines, use gentle reciprocating action and avoid cutting too deep in a single pass.

UNEVEN SEGMENT WEAR

Possible Causes

• Wet cutting – insufficient water on one side

• Excessive cutting pressure, caused by too high infeed, results in the blade core bending and flexing. Metal fatigue will eventually cause the core to crack.

• Worn shafts, damaged bearings, or blade incorrectly mounted.

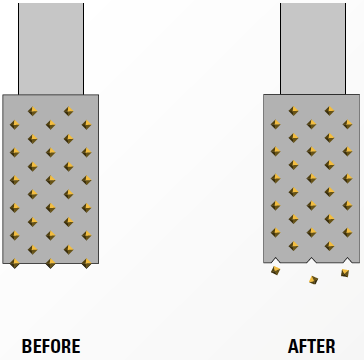

RAPID WEAR

Possible Causes

• Blade specification is causing the diamond to be over-exposed. Use a blade with a harder bond system.

• If the blade wears out of round this will increase the wear normally due to bad bearing, worn shaft or the blade specification being too hard for the material.

• An inadequate water supply can cause damaged or blocked water tubes.

• Softening of the blade specification and low blade speed can be caused by loose drive belts.

BLADE NOT CUTTING

Possible Causes

• Check that specification is correct for the material. Dull blades can be sharpened by cutting a soft abrasive material.

• Machine drive belts need re-tightening or the machine has insufficient horsepower for the specification being used.

• Check direction of rotation.

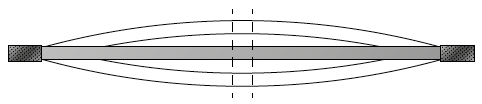

TENSION LOSS

Possible Causes

• Blade core overheated. For wet cut blades ensure sufficient water supply.

• Check machine is running at correct rpm, that the flanges are of the correct and same size and that there is no wear on the machine bearing.

• The blade is deviating in the cut because it is too hard for the application.

• Ensure that the blade is not spinning on the spindle and that it is secure.

• Ensure that the blade is cutting in straight lines only.

SEGMENT CRACKS

• Use a blade with a softer bond system, as the blade specification may be too hard for the material being cut, causing hammering in the cut.

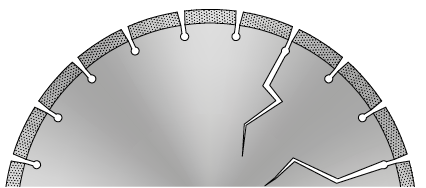

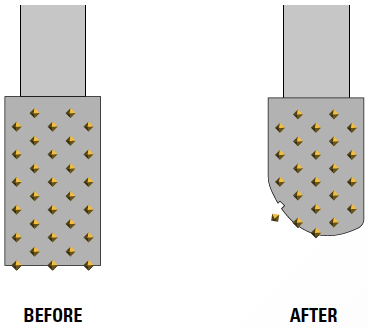

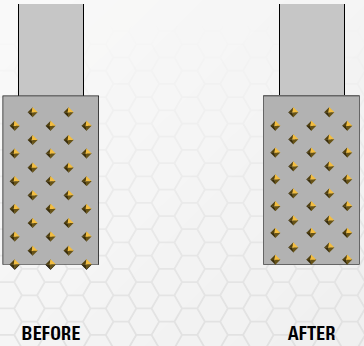

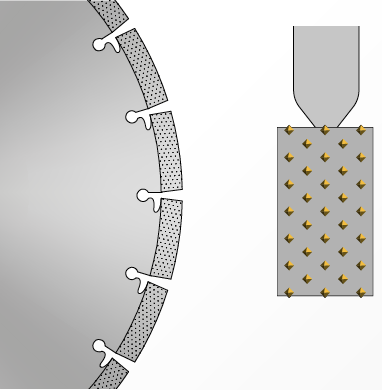

UNDERCUTTING

The effect of premature wear of the steel core is a particular problem in asphalt, fresh concrete and other highly abrasive materials. Segment loss may result from the steel core wearing to a knife edge just below the segment.

Possible Causes

• Make sure that the blade specification has offset segments to assist removal of the slurry from the cut.

• Make sure that the blade is not cutting below the asphalt into the sub-base. Constant rubbing of the loose material causes premature wear and has no beneficial effect on the cut surface.

• Make sure that the water supply is correct as increased water flow will wash slurry from the contact area and reduce undercutting.

If a product will not cut because the blade has “glazed over” then “open” the blade up by running it through abrasive materials. If a blade is wearing prematurely then use a blade with a harder bond.

© 2024 Cat® Diamond Tools