THE SEGMENT

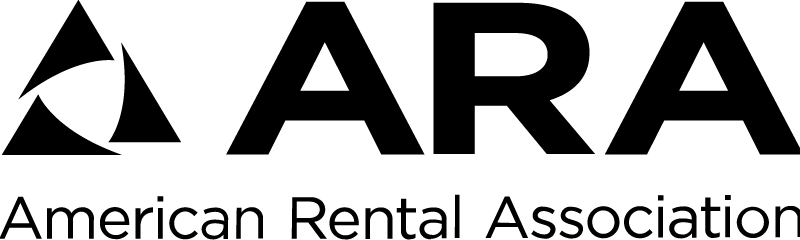

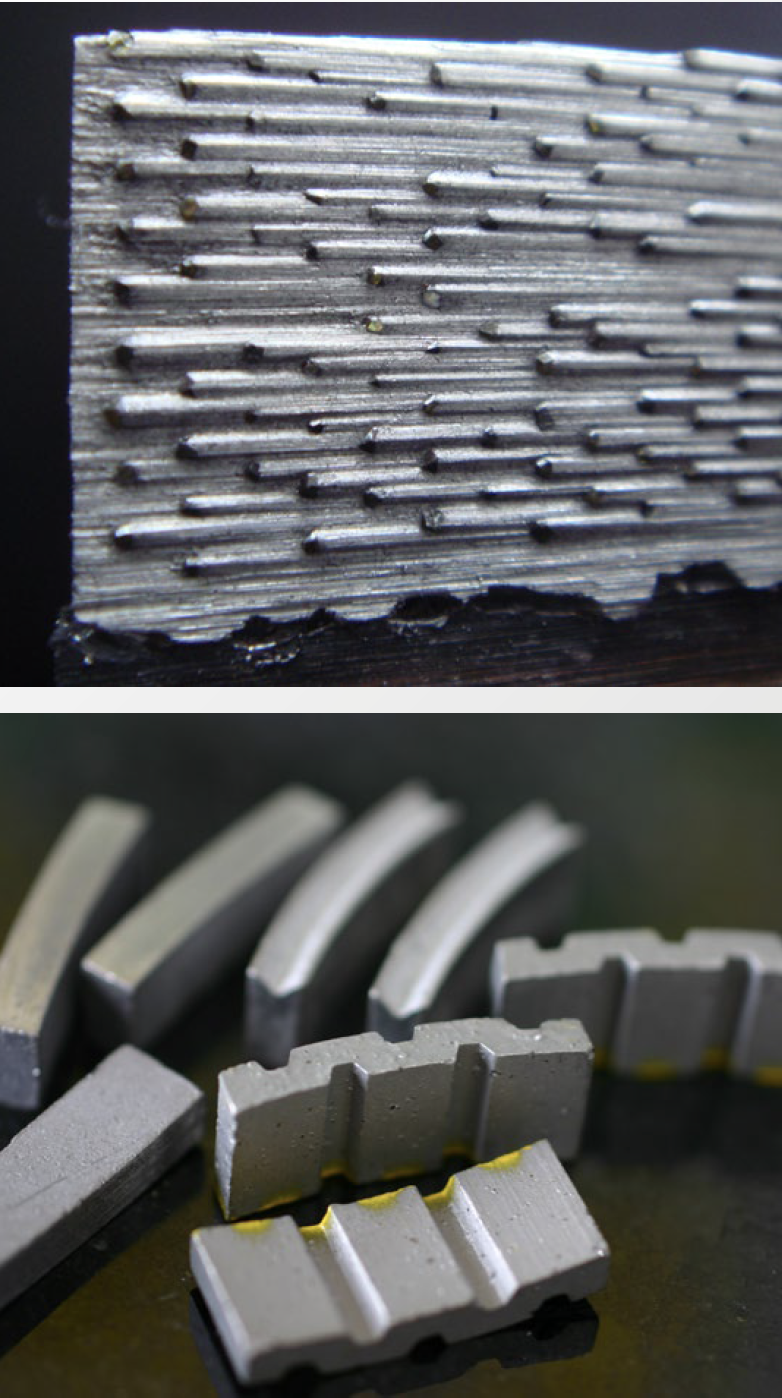

Segments are heated dependant on the metal powders used to temperatures of around 1300°C to form the desired product that comes in a variety of sizes and shapes dependent upon their purpose and application. The segment is made wider than the steel core to which it is to be attached called the kerf. This difference in dimension allows the blade to cut freely without binding the core against the application when it is in the cut. Clearance helps to remove the residue and debris from the cut and thus stops the core blank from wearing prematurely which would result in blade failure.

Deep draft protection segments are attached to blades that may encounter abrasive applications to also help in the removal of the abrasive slurry from the cut. This also eliminates any undercutting of steel. The part of the segment that is to be attached to the core is manufactured without diamonds and this is usually called “freeback”. This transitional area is to be adhered to the core, usually by laser welding. Any impurities or foreign bodies within this weld area would jeopardise the stability of this area and could finally result in segment loss.

THE CORE

Cat® diamond cores are made from high alloy, heat treated steel. A bore hole is milled out of the center to the required size. Radial slots or gullets are machined out of the outer perimeter to facilitate the attachment of the segments. These can be machined in a variety of forms, wide gullet, narrow gullet, recessed or many others dependant on the application.

The various types of gullet are needed for different cutting applications. They enhance the performance of the product and its cutting characteristics. The different shaped gullets improve water and air flow around the periphery of the blade and help dissipate the heat and slurry out the cut which is critical to the cutting process and life of the blade.

The segments are laser welded or brazed onto the core to complete the finished product. The core itself must be balanced and true. This is checked throughout our manufacturing process both before and after segment attachment. It is also checked again after dressing. The term “dressing the segment” refers to grinding away the metal matrix or bond by use of a specially designed grinding wheel. This exposes the primary layer of diamond crystals ready for use by the operator.

Core bit barrels are made with seamless tubing or from rolled or welded steel. Due to the high RPM’s the core is subjected to, it is critical that the tube is true, straight and round. Out of round tubes will result in core drill failure or premature uneven wear of the barrel.

© 2022 Cat® Diamond Tools